FALL PROTECTION SYSTEMS

A personal fall-arrest system is generally required whenever an individual is at risk of falling from working at heights or from an elevated position. Properly designed system should include three components:

An anchor point will serec as a secure connection point for lifelines, lanyards or deceleration devices.

A full-body harness designed to distribute fall-arrest forces over thighs, pelvis, waist, chest and shoulders; if a fall occurs, the ring located in centre of the back will hold worker in an upright position until rescued.

A Connecting device wsuch as lanyard, deceleration apparatus, lifeline or a combination of these items with locking snap hooks.

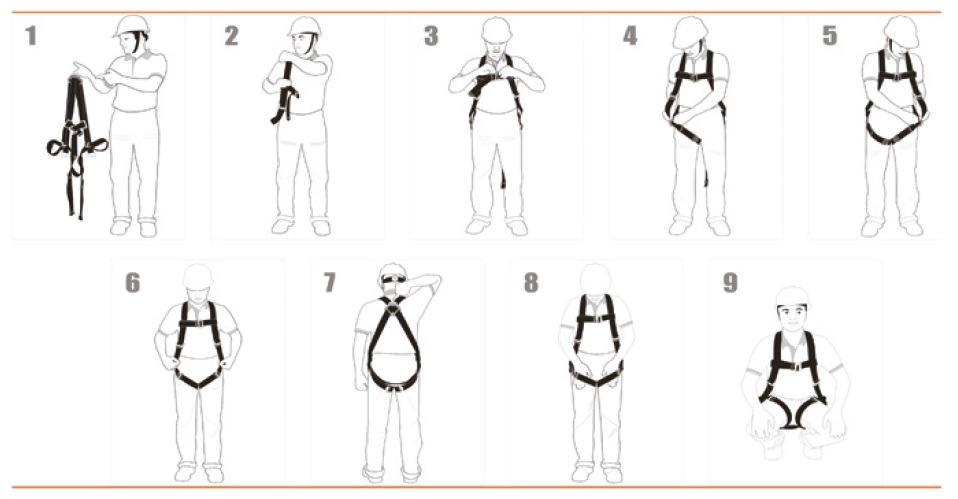

How to wear a harness

The Full Body Harness can be worn following these simple steps

The work Positioning Belt and Lanyard can be worn as per the following easy steps